> Grain Drying Tower

- - Corn Drying Tower

- - Rice Drying Tower

- - Wheat Drying Tower

- - Sorghum Drying Tower

- - Seed Drying Tower

- - Soybean Drying Tower

> Grain Dryer

> Contact Us

Contact: Manager Liu

TEL:18137228199

Email:hnfengsheng@126.com

Add:By the way West Road North opened white Huanglong Industrial Zone

Product

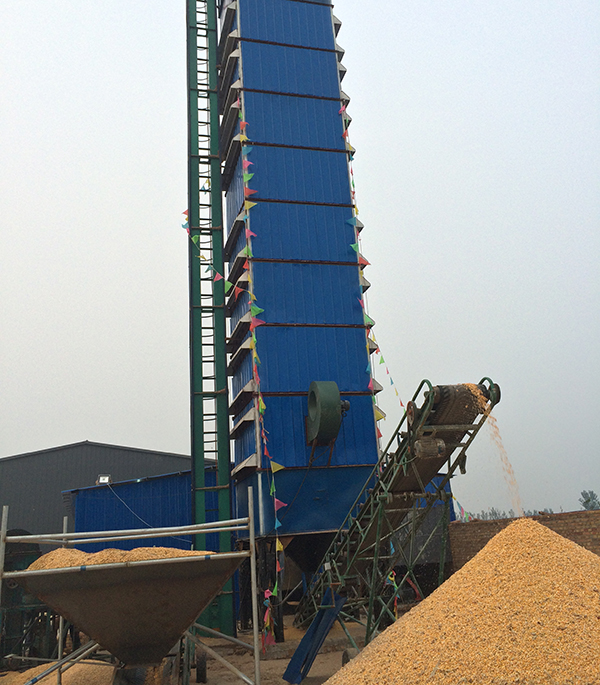

Corn Dryer-4

Use:

This equipment has the advantages of reliable operation, reasonable structure, high efficiency, uniform precipitation, precipitation gradient, a one-time use of a wide range of advantages, especially in the northern area of our country high moisture corn in Alpine dry season the job is the ideal product, the drying effect of drying of corn, wheat and rice are good, soybeans and other grains the implementation of drying operation of feed grain, grain, seed grain can be, is an ideal equipment for farms, grain, grain and oil processing plants and wine making, pharmaceutical and feed industries drying operation.

Design basis and parameters

The design is based on the main technical standards:

1, grain dryer technical conditions: GB8867-88

2, grain dryer test method: GB6970-86

3, hot blast stove technical conditions: JB/T6672.1-2001

4, hot blast stove test method: JB/T6672.2-2001

And all kinds of technical conditions.

Basic parameters of this equipment

1, raw water is 28-30%H2O

2, the ambient temperature is an average of -10

3, flow time is 4.5-6 hours

4, the processing capacity of 5-20 tons / hour

5, the surface wind speed 4-6m/ seconds

6, medium temperature 60-160

7, heat transfer efficiency of 73%

8, low calorific value of 5000kcal/kg

Structure and process flow:

The heat source part of the equipment can be divided into hand burning, burning machine, combustion chamber and heat exchanger manufacturing was two, according to the heating capacity of the stacked segment installation or installation, the heat exchange part is made of metal, the heat transfer tubes and plate combination, flue gas and air operation return heat, smoke, the wind prevails, get clean hot air for drying grain, adjust the state of combustion and heat transfer ratio from the smoke temperature controller, to ensure that the air temperature is stable, uniform grain drying, no pollution.

Dryer all metal structure, arranged in a top-down storage, drying, tempering, reversing, drying, cooling, etc. the grain discharging section, hot air from the middle air chamber into the tower, the wind distributor uniform distribution sent to the air inlet angle box. After grain layer heat exchange after the tide angle box exhaust tower, moisture discharging opening is provided with a metal shutters, to eliminate the air flow of the tide.

Heat exchanger, air drying tower and heating pipes are made of double metal shell, sandwiched fireproof rock wool insulation, in order to improve the effect of drying, air and gas pipeline is provided with a smoke, air temperature controller to adjust the fan hood, working condition, adjust the temperature of hot air flow pressure parameters to ensure ideal drying operation operation.

The ventilator is arranged in the exhaust smoke box at the mouth of the tobacco road in the heat exchanger to form a negative pressure device, and the blower is arranged in the air inlet of the heat exchanger, the air to form a positive pressure in the heat exchanger, in order to ensure the purity of hot air.

This device is provided with a recovery device of waste heat exchanger and dust chimney, in order to improve the thermal efficiency and reducing exhaust soot content, meet the national emission standards.

The equipment adopts the following technological process:

Grain - Grain - water - drying - tempering - reversing - drying - tempering - drying - tempering - cooling - grain

Installation and commissioning

1, users put the line, excavation, concrete pouring equipment according to the basic conditions and the local geological meteorological conditions, casting quality health should pay attention to the foundation, ensure the size and location of the right to the left, and to ensure the position and level of buried iron, error control within 1/1000, to carefully checked before installation.

2, inventory of all parts of the equipment, to ensure that the specifications, models, the number of accurate.

3, were assembled in a hot blast furnace, drying tower, hoisting machine, main fan, ventilator, electric control cabinet and other major components.

4, according to the basic position and the requirements of the overall image of the major components in place, and to ensure that the location of the center and the relative relationship.

5, School of inspection, to ensure that the installation position of the correct size, the hot blast furnace, drying tower, lifting machine, major components of the main fan, fan, electric cabinet hoisting, ensure the installation error is less than 1/1000, and reliable.

6, join the Department of smoke and air pipeline and the auxiliary.

7, each part of the motor and transmission parts in place, and put the wires, cables. And according to the technical requirements of masonry work.

8, the final part of the safety protection devices installed in place, and the overall quality of the installation of all checks and proofreading.

9, after the end of the installation of the transmission of the manual operation of the machine, check the true error can be carried out on the machine for a single test run.

No error can be used for on-line operation no-load operation 1-2 hour test 10, single, and oil to each lubricating part.

11, ignition, coal, the hot stove was smoked. 3-5 day, at this time, the main fan must be opened in order to avoid the empty furnace burning and destruction of the furnace body and heat exchange part.

12, and then began to clear the grain on the grain, and do a comprehensive inspection, eliminate hidden dangers, do a good job in the preparatory work.

Operation and maintenance:

1, drying operation is a joint operation of many people, must strengthen the organization and management, the establishment of full management of the captain, and the establishment of the effective rules and regulations, strict management.

2, the staff must be trained and assessed before the mount guard operation, and be responsible for their own work to coordinate the relationship between the various links.

3, mechanical and electrical personnel to do the inspection, timely processing problems in strict accordance with the mechanical and electrical properties and the use of the need to operate well.

4, the fireman to ensure normal combustion state of hot blast stove, to do qinguo Qin, Qin Qing, Tim, must first open the main fan start fan at the time of ignition, shutdown must stop the ventilator, the air temperature dropped to 40 degrees below and then stop the main fan.

5, grain personnel should stick to their posts, when a grain storage section